Using state-of-the-art technology, we manufacture piston rings that meet and exceed industry standards.

Our products are built to last, providing reliable sealing and superior performance even under extreme conditions

We deliver our piston rings to customers across the country, ensuring timely and secure shipments.

At KRK Industrial, we go beyond manufacturing products; we create solutions that empower your engines to perform at their peak. Our dedicated research and development team continuously innovates to deliver the best possible products, ensuring our piston rings keep your engines running smoothly even in the most demanding conditions.

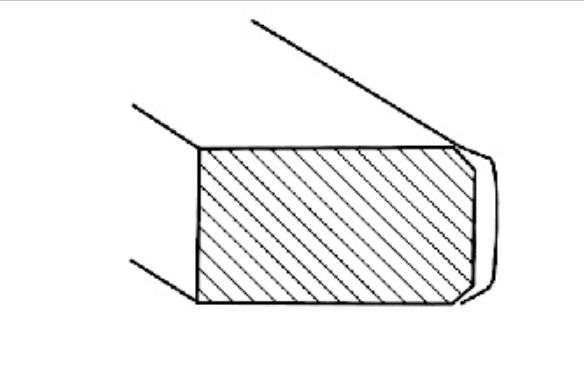

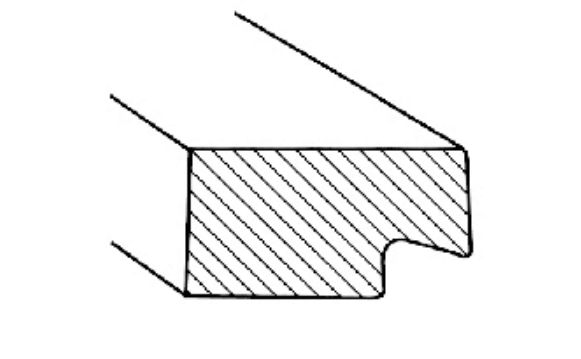

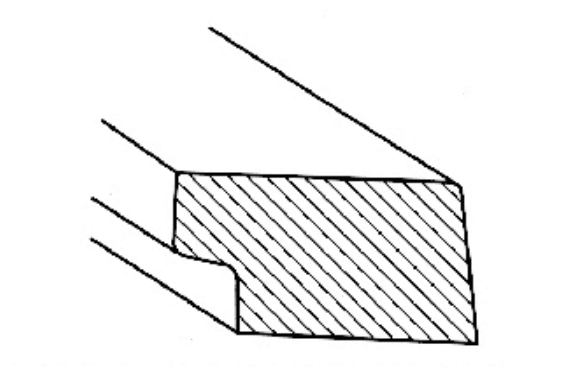

Top Rings

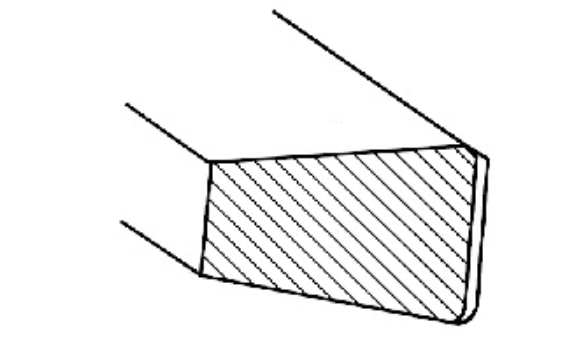

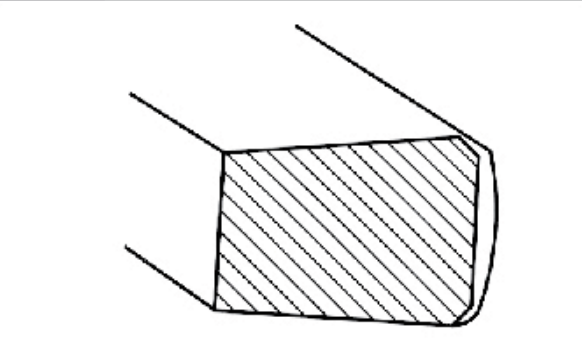

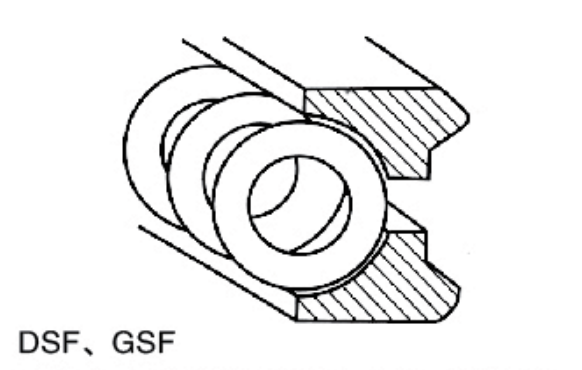

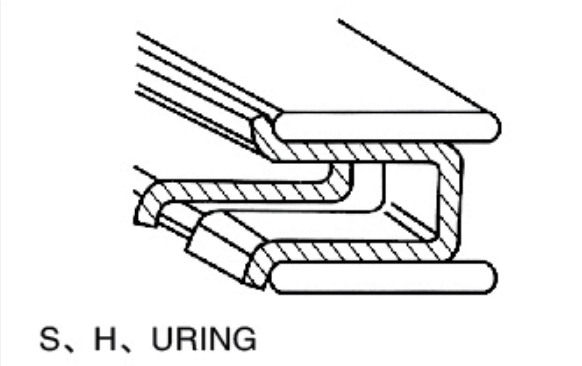

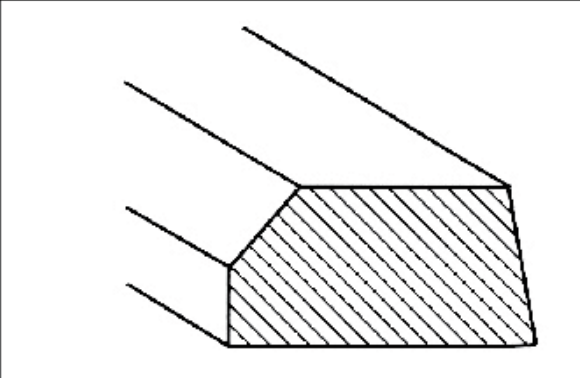

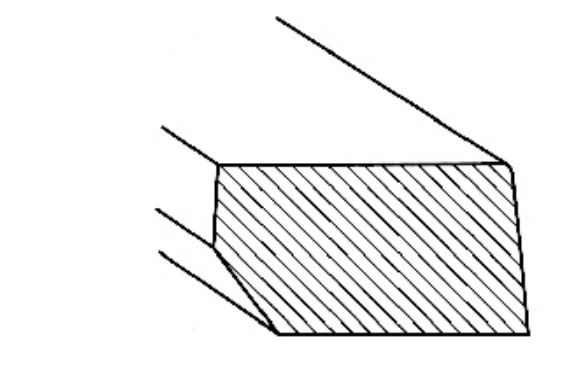

Compression Rings

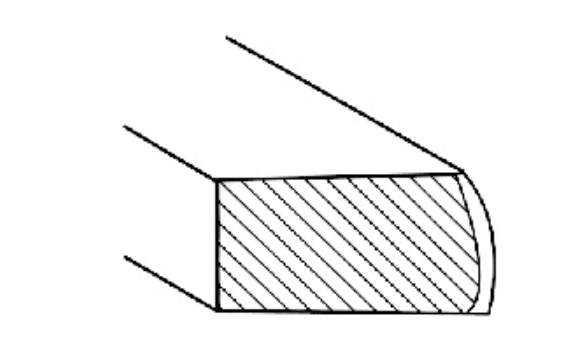

Oil Rings

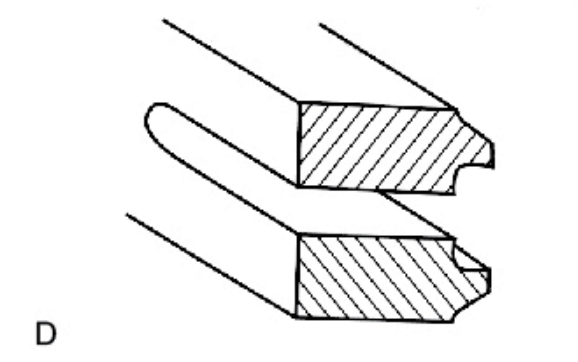

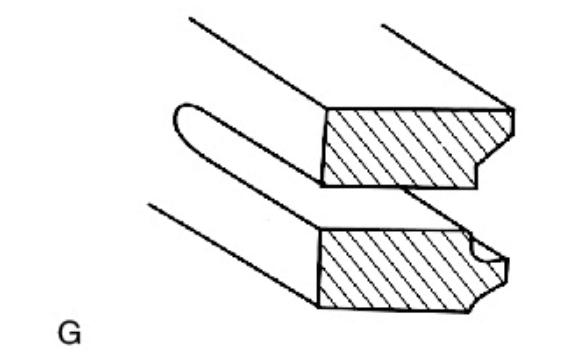

Edge Features

– Premium Materials: We use only the finest-grade alloys and advanced coatings to ensure maximum wear resistance and thermal stability.

– Innovative Engineering: Our piston rings are designed with precision engineering to provide a perfect seal, reducing friction, enhancing power, and minimizing oil consumption.

– Stringent Quality Control: Each piston ring undergoes rigorous testing to meet and exceed OEM and international quality standards, giving you peace of mind and exceptional performance.

– Custom Solutions: Need something specific for unique applications? KRK Industrial offers custom piston ring solutions tailored to your needs.

Enhance and protect your surfaces with our top-quality coating solutions. At KRK Industrial, we offer advanced coatings designed to resist corrosion, weathering, and wear. Whether for industrial equipment, building exteriors, or decorative finishes, our coatings provide long-lasting durability, aesthetic appeal, and protection against harsh conditions. Discover the best way to extend the life and beauty of your surfaces with KRK Industrial

Chrome plating,CR

The electrodeposited hard chrome coating combines excellent wear resistance with high resistance to scuffing. This accounts for the superiority of chromed rings to uncoated rings and surface treated rings. Experience shows that a chromed ring reduces wear of the cylinder running surface to about 50% and wear of the whole ring pack to about 30% the values obtained with nonchromed rings.

Molybdenum Coating,MOL,MO

To avoid scuffing the periphery of the rings is coated with molybdenum, a process that has yielded excellent results. Molybdenum has a very high melting point(2620°C) and good thermal conductivity, factors which account for the high resistance to scuffing and scoring. Another advantage is the porous structure which forms as the molybdenum is sprayed on, as this promotes good lubrication.

Plasma Spray Coating,PS

In this process the coating materials are melted in a plasma flame at very high temperatures (up to about 15000°C) and sprayed onto the ring running surface. At such high temperatures almost all elements can be melted, enabling the production of metallic, metal-ceramic and all ceramic mixed coatings with different characteristics.Plasma spray coatings, which possess high wear, scuff and breakout resistance and high inherent strength, while causing only limited cylinder wear, are today used very successfully in production.

Phosphating,P

The process is employed to speed up and improve seating-in of the rings. The surface of the ring is transformed by chemical treatment to phosphate crystals

Nitriding,NT

Surface treatment by nitriding to reduce wear of compression rings (mainly steel rings).

Chromium-Ceramic Coating, CK

The CK coating withstands higher thermal and mechanical loading than the exisiting chromium, molybdenum and plasma coatings, though these tried and tested coatings lose none of their significance. In the appropriate designs they continue to satisfy the special demands in the tribological system.

Our process at KRK Industrial is designed to ensure that you receive top-quality piston rings tailored to your needs in the most efficient way possible. Here’s how it works

- Ideal for passenger cars, commercial vehicles, and heavy-duty engines

- Features: High resistance to wear, excellent sealing properties, and optimal heat dissipation

- Applications: Heavy machinery, construction equipment, and manufacturing plants

- Customizable to fit various industrial machinery

- Features: Robust design, resistance to extreme pressures, and extended lifespan

- Applications: Heavy machinery, construction equipment, and manufacturing plants

- Built for endurance in harsh marine conditions

- Features: Corrosion resistance, long-lasting durability, and efficient sealing under pressure

- Applications: Marine engines, fishing boats, and cargo ships

At KRK Industrial, we take pride in the trust and satisfaction of our clients nationwide. Here’s what people are saying about our high-quality piston rings and exceptional service:

I’ve tried other piston ring manufacturers, but none compare to the quality of KRK Industrial. Their precision-engineered rings have exceeded our expectations, and we trust them for all our industrial engines.

We’ve been using KRK Industrial piston rings for our fleet, and the difference in performance is undeniable. Their rings are durable, reliable, and have significantly improved our engine efficiency. Highly recommended!

The KRK Industrial team is always there when you need them. From selecting the right product to installation advice, their customer support is outstanding. It’s clear that they care about their customers

We are here for you!