High performance Oil Rings

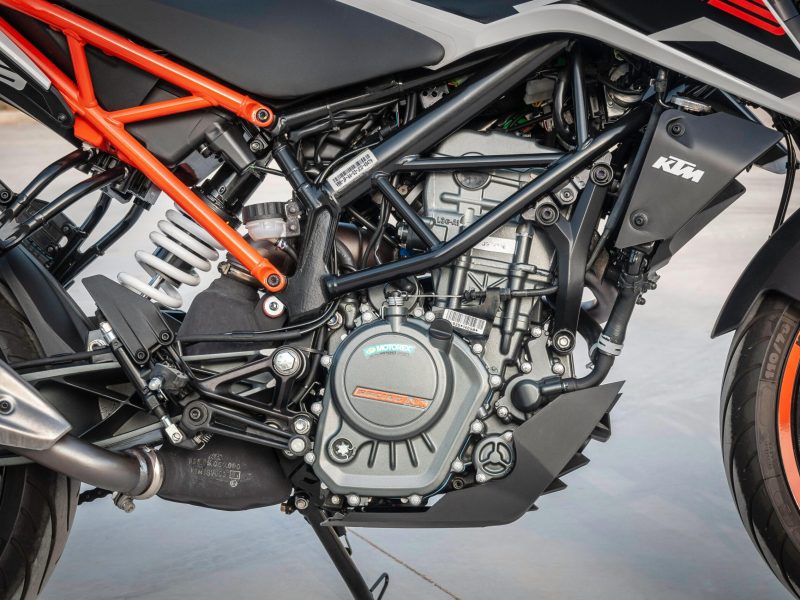

Engine lubricating oil performs an essential protective function in the engine by allowing parts to slide and preventing direct metal-to-metal contact (reducing friction *1) that causes wear and, in the worst case, total engine failure. Engine oil reduces operating friction, making the engine more efficient, while also cooling critical engine components and trapping harmful dirt particles.

+

Trusted by 813 clients

We Have Trust From 3+ Countries Worldwide.99% Satisfaction.

Oil ring characteristics

Commitment to quality – every piston ring is rigorously tested to ensure long-term performance.

Improve engine performance

Compatible with 3,000 types of engines

Extended service life

Time extension 20-30%

Reduce fuel consumption

15%-25% reduction

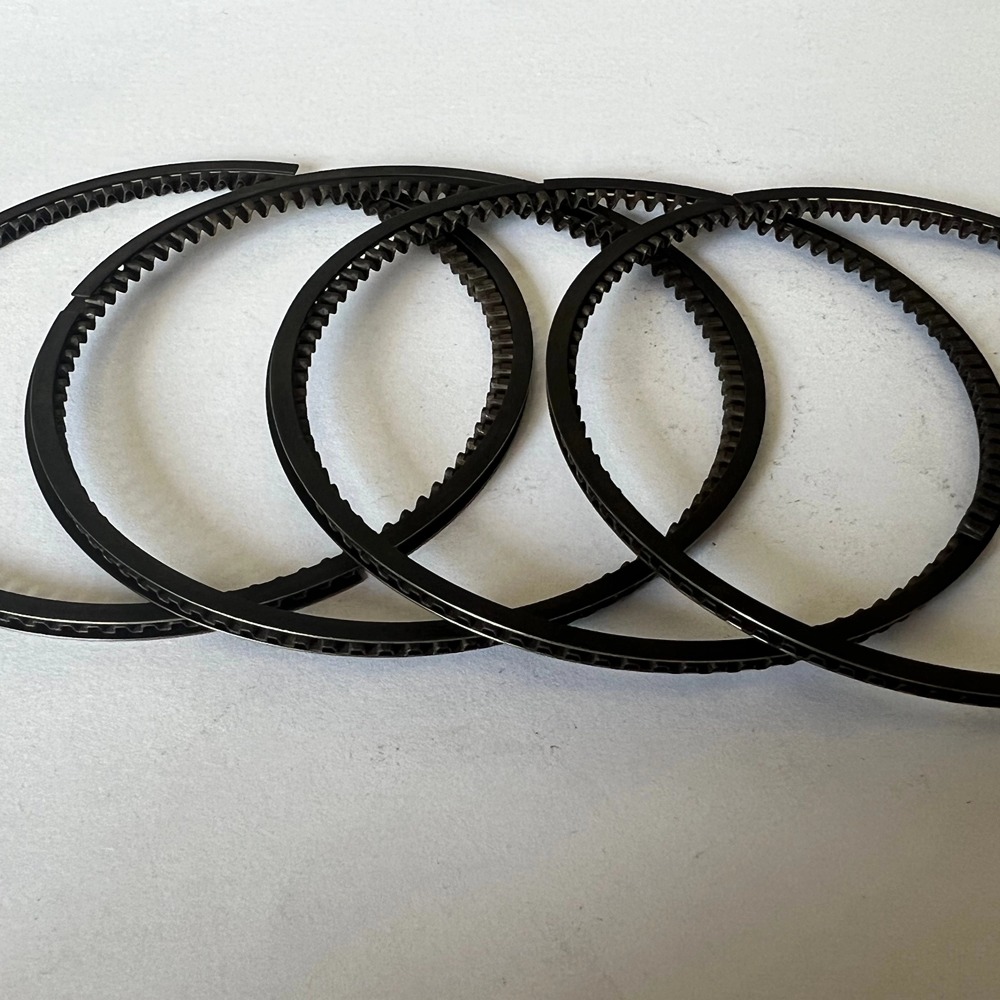

Type of oil ring

Oil ring-combination

big wave

- Control and monitor oiling

- Design with multiple thin layers

- Efficient to burn and low to emit

Oil ring-combined wavelet nitriding

- Oil removal from the cylinder wall

- Thick Build with Oil Scraper Edge

- Used in High-Performance Engines

Oil Ring Chrome Lining External Chrome Phosphating

- Provides effective sealing and lasts

- Two side rings and one expander

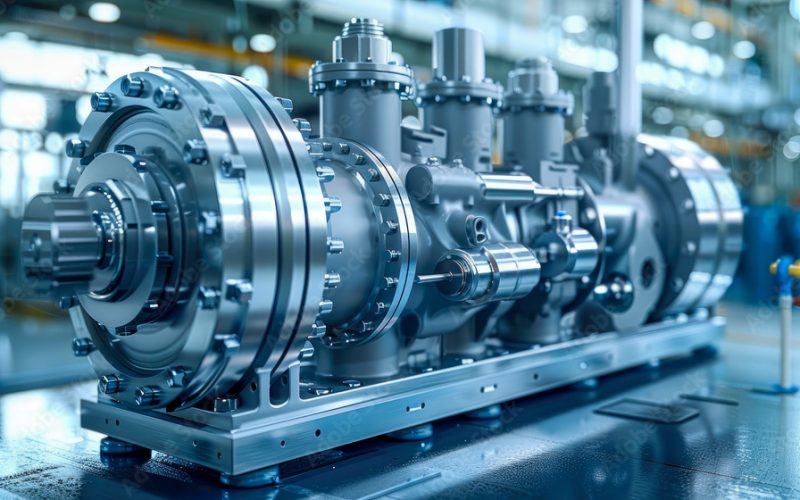

- Large Machinery and Power Plants

Oil ring-combined

U-shaped

- Strengthen sealing

- Resistant to heat and pressure

- Racing engine or special vehicle

Coatings & Materials

- Cast Iron

- DUCTILE IRON (NODULAR IRON)

- NI-RESIST

- Bronze

- Dry Films

- Silver Plating

- Chromium Plating

- Phosphate Coatings

- Phosphating

- Anodizing

- Plasma Spraying

- Nitriding

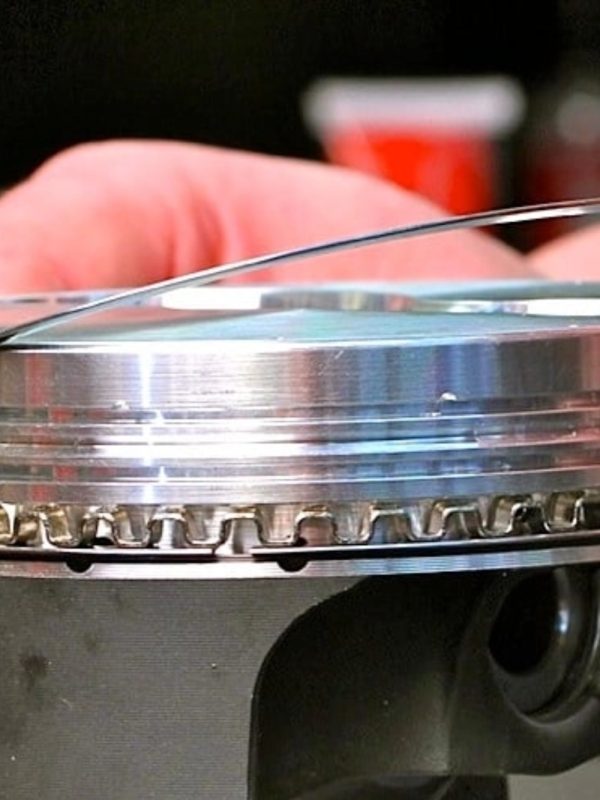

Manufacturing process overview

01

material selection

Choose high-quality alloy materials such as cast iron or steel.Cut the material into a suitable blank shape and prepare it for subsequent processing

02

Rough casting and processing

Carry out preliminary mechanical processing such as turning and milling on the blank to form the rough shape and size of the oil ring

03

heat treatment

Heat treatment, such as quenching and tempering, is performed on the initially processed oil ring to improve its hardness and wear resistance.

06

Testing and packaging

Strict size, hardness and surface quality inspection of oil rings are carried out to ensure that they meet the design requirements.Pack the qualified oil rings and prepare them for shipment from the factory

05

Surface treatment

Surface treatment of the oil ring, such as chromium plating or phosphating, to improve its corrosion resistance and lubrication performance

04

Precision Machining

The oil ring is brought to its final size and surface finish through precision machining such as grinding and polishing

Quality check 1:1

Each piston ring undergoes a meticulous 1:1 quality check to ensure it meets strict specifications. This process guarantees optimal performance and durability in every engine application.

0 complaints

Our products have zero customer complaints.You just collect the money and expand your own brand.

3 Years

We've had zero customer complaints for three years. This shows our commitment to excellence and customer satisfaction.

Quality control is a continuous process throughout the piston ring manufacturing process. Rings are inspected at various stages to ensure they meet strict quality standards. This includes dimensional inspection, surface finish evaluation, and coating integrity verification. Rings that do not meet the specified criteria are rejected.