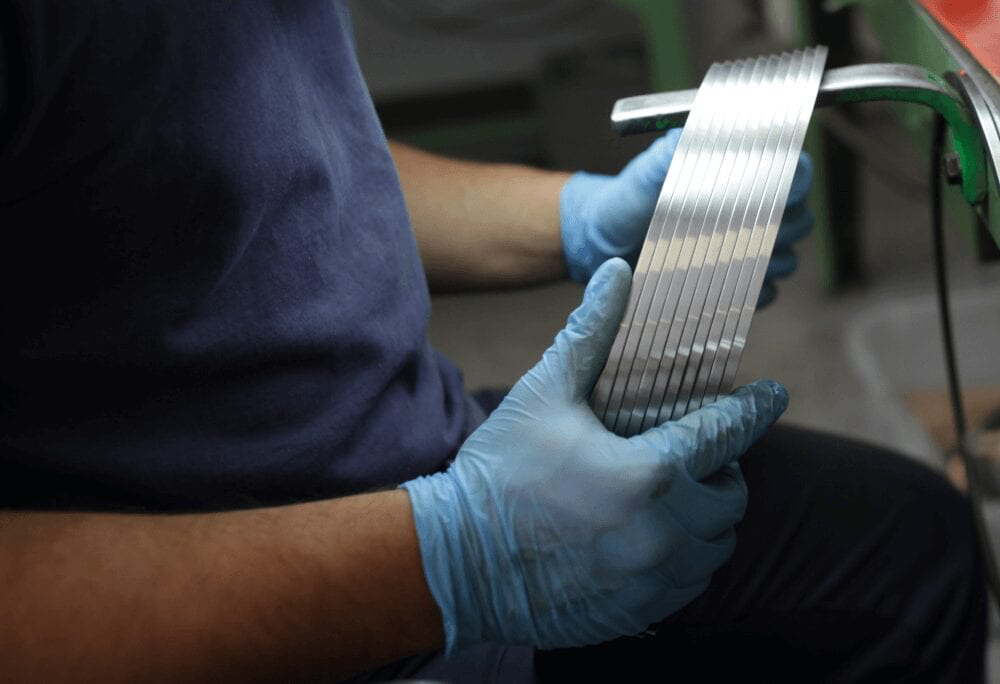

Welcome to the world of piston rings! These small but mighty components play a crucial role in the functioning of internal combustion engines. Whether you’re an automotive enthusiast, a DIY mechanic, or simply curious about how engines work, this blog post will provide you with valuable insights into the world of piston rings.

Piston rings have a rich historical context that dates back to the early days of engine development. They were first introduced in the late 19th century as a solution to reduce oil consumption and improve engine performance. Since then, they have undergone significant advancements in design and materials, resulting in more efficient and durable engines.

So, if you want to dive deeper into the fascinating world of piston rings and gain a better understanding of their role in engine mechanics, keep reading!

Key Takeaways

- Understanding the role of piston rings is crucial for maintaining engine health and performance.

- Checking and adjusting ring gaps is important to ensure optimal engine function and prevent damage.

- Recommended gap clearances should be followed to avoid issues such as blow-by or loss of compression.

- Properly measuring ring gaps is essential for accurate adjustments and reliable engine operation.

- Adjusting the gap according to manufacturer specifications can improve engine performance and fuel efficiency.

- Avoid common mistakes like incorrect gap measurements or improper installation to prevent engine problems.

- Regular maintenance, including checking and adjusting ring gaps, is key to prolonging the lifespan of piston rings and the engine.

Understanding Piston Rings

Role of Piston Rings in an Engine

Piston rings play a crucial role in the operation of an engine. These small but mighty components are responsible for sealing the combustion chamber, allowing the piston to move smoothly within the cylinder while maintaining optimal compression. Without piston rings, engines would struggle to generate power efficiently and effectively.

Types of Piston Rings and Their Functions

There are typically three types of piston rings: compression rings, oil rings, and oil ring expanders. Each type has its own specific function that contributes to the overall performance of the engine.

Compression rings are located near the top of the piston and are responsible for sealing the combustion chamber. They prevent the fuel-air mixture from escaping into the crankcase during the combustion process, ensuring maximum compression and power output. These rings also help regulate oil consumption by scraping excess oil from the cylinder walls.

Oil rings, on the other hand, are positioned lower on the piston. Their primary function is to control the distribution of oil along the cylinder walls. They prevent excessive oil from entering the combustion chamber while also ensuring proper lubrication of the piston and cylinder walls. Oil rings consist of an oil ring expander and an oil ring package, which work together to maintain optimal oil control.

Importance of Proper Installation of Piston Rings

Proper installation of piston rings is vital for engine performance and longevity. Incorrect installation can lead to various issues such as loss of compression, increased oil consumption, and decreased power output.

One critical aspect of installation is ensuring that each ring is correctly positioned in its designated groove on the piston. This ensures a proper seal and prevents any gaps or misalignment that could compromise engine performance.

It is essential to consider factors such as ring end gap and cylinder diameter during installation. Ring end gap refers to the clearance between the ends of the ring when installed in the cylinder. It is crucial to follow manufacturer specifications to ensure the correct gap for optimal performance. Cylinder diameter, on the other hand, determines the size of the rings needed for a specific engine. Using the wrong-sized rings can result in poor sealing and inefficient combustion.

Checking Ring Gaps Importance

Ensuring Proper Ring Gap Measurements

Before installing piston rings, it is crucial to check the ring gaps to ensure optimal engine performance. The ring gap refers to the space between the ends of the piston ring when it is placed inside the cylinder bore. This small but significant gap plays a vital role in maintaining proper compression and controlling oil consumption within the engine.

Impact on Engine Performance

Incorrect ring gaps can have a detrimental effect on the overall performance of the engine. If the ring gaps are too small, they can cause excessive friction and heat buildup, leading to increased wear and potential damage to the rings and cylinder walls. On the other hand, if the ring gaps are too large, it can result in poor combustion sealing, loss of compression, and decreased power output.

Risks of Not Verifying Ring Gaps

Neglecting to verify ring gaps before installation can lead to various risks and issues. Firstly, inadequate ring gaps can result in excessive blow-by, where combustion gases escape past the rings into the crankcase. This not only reduces engine efficiency but also leads to increased oil contamination and consumption. Over time, this can cause engine performance degradation and potentially lead to costly repairs.

Secondly, improper ring gaps can contribute to decreased compression levels. Compression is essential for efficient combustion, and any leakage due to incorrect ring gaps can compromise this process. As a result, the engine may experience reduced power output, sluggish acceleration, and decreased fuel efficiency.

Furthermore, failing to check ring gaps can also result in premature ring wear. When the gaps are not within the recommended specifications, the rings may not be able to expand or contract properly during engine operation. This can lead to accelerated wear on both the rings and cylinder walls, reducing their lifespan and necessitating early replacement.

Recommended Gap Clearances

Types of Engines and Their Recommended Clearances

There are various types of engines, each with its own recommended gap clearances for piston rings. These clearances are crucial for optimal engine performance and longevity. Let’s take a closer look at the recommended gap clearances for different types of engines:

Gasoline Engines

In gasoline engines, the recommended minimum gap tolerances for piston rings typically range from 0.0015 to 0.003 inches per inch of cylinder bore diameter. This means that for every inch of cylinder bore diameter, the piston ring gap should be between 0.0015 and 0.003 inches. For example, if the cylinder bore diameter is 3 inches, the recommended ring gap would be between 0.0045 and 0.009 inches.

Diesel Engines

Diesel engines, on the other hand, require slightly larger gap clearances compared to gasoline engines due to higher operating temperatures and pressures. The recommended minimum gap tolerances for diesel engine piston rings usually range from 0.002 to 0.004 inches per inch of cylinder bore diameter. Similar to gasoline engines, these clearances ensure proper ring sealing and prevent excessive blow-by.

Factors Influencing Ideal Gap Clearances

Several factors influence the ideal ring gap clearances for piston rings. These factors include:

- Engine Type: As mentioned earlier, gasoline and diesel engines have different recommended gap tolerances due to variations in operating conditions.

- Cylinder Bore Diameter: The size of the cylinder bore directly affects the recommended ring gap clearance. Smaller bore diameters generally require smaller gaps, while larger bore diameters necessitate larger gaps.

- Material and Design: The material composition and design of the piston rings also play a role in determining the ideal gap clearances. Different materials expand and contract at different rates, affecting the required gap size.

- Operating Conditions: The operating conditions of the engine, such as temperature and pressure, can impact the ideal ring gap clearances. Higher temperatures and pressures may require larger gaps to accommodate thermal expansion.

Consequences of Incorrect Gap Clearances

Using incorrect gap clearances for piston rings can have detrimental effects on engine performance.

- If the gap is too small, the rings may become jammed or seize in the cylinder bore, leading to increased friction and potential damage to the rings and cylinder walls. This can result in decreased compression, reduced power output, and increased oil consumption.

- On the other hand, if the gap is too large, excessive blow-by can occur, leading to decreased compression and increased oil consumption. This can also result in reduced power output and increased emissions.

It is crucial to follow the manufacturer’s recommendations for ring gap clearances to ensure proper engine function and longevity.

Gap Significance for Engine Health

Correlation between Ring Gaps and Engine Health

The gap clearance in piston rings plays a crucial role in maintaining the overall health and performance of an engine. The ring gaps, which are small spaces intentionally left between the ends of the piston rings, have a direct impact on various aspects of engine operation. These gaps are not just arbitrary spaces; they serve specific purposes that contribute to the optimal functioning of the engine.

One of the primary reasons for having ring gaps is to allow for thermal expansion. As the engine heats up during operation, the piston and cylinder expand due to the high temperatures generated by combustion. Without proper clearance, the expanding piston rings could seize against the cylinder walls, leading to catastrophic engine failure. By incorporating ring gaps, manufacturers ensure that there is sufficient room for expansion, preventing any potential damage caused by thermal expansion.

Adjustments and Engine Longevity

Properly adjusting the ring gaps is essential for ensuring the longevity of an engine. The ideal gap clearance is determined based on factors such as engine design, materials used, and intended operating conditions. If the ring gaps are too narrow, they can lead to excessive friction and increased wear between the rings and cylinder walls. This can result in decreased engine efficiency and a shorter lifespan for critical engine components.

On the other hand, if the ring gaps are too wide, it can lead to compression loss within the combustion chamber. This can result in reduced power output, decreased fuel efficiency, and increased emissions. Wider ring gaps can also allow oil to enter the combustion chamber, leading to oil consumption and potential carbon buildup on critical engine components. Therefore, finding the right balance in ring gap adjustments is crucial for maintaining optimal engine performance and maximizing its lifespan.

Role in Preventing Compression Loss

Ring gaps also play a vital role in preventing compression loss within the engine cylinders. The piston rings create a seal between the piston and cylinder walls, ensuring that combustion gases are contained within the combustion chamber. If the ring gaps are not properly adjusted, it can result in leakage of these gases, leading to a reduction in compression pressure. This can have a significant impact on engine performance, causing decreased power output, rough idling, and poor fuel efficiency.

Measuring Ring Gaps Correctly

Proper Techniques for Accurate Measurements

To ensure optimal engine performance and longevity, it is crucial to measure piston ring gaps correctly. The respective ring gaps play a vital role in maintaining a reliable ring seal and preventing any loss of compression. Here are some essential techniques to follow when measuring ring gaps accurately:

- Use the Right Tools: To obtain precise measurements, it is essential to have the appropriate tools at hand. A ring gap tool, specifically designed for this purpose, is highly recommended. This tool ensures consistent and accurate measurements, eliminating any guesswork or inaccuracies.

- Clean the Rings: Before taking measurements, make sure to clean the rings thoroughly. Any debris or residue on the rings can interfere with accurate readings. Use a mild solvent or cleaning solution to remove any dirt or oil from the rings. Once cleaned, dry them completely before proceeding with the measurement process.

- Position the Ring: Place the ring in the cylinder bore where it will be installed. Ensure that the ring is positioned perpendicular to the cylinder wall to obtain accurate gap measurements. This step helps eliminate any potential errors caused by misalignment.

- Measure at the Appropriate Location: Different rings have specific requirements regarding where to measure the gap. For example, top rings typically require measuring at the top of the cylinder bore, while second rings may require measuring lower down in the bore. Refer to the manufacturer’s specifications or recommendations for each ring type.

- Apply Gentle Pressure: When measuring the gap, apply gentle pressure to compress the ring slightly. This mimics its position during engine operation and provides a more accurate measurement. Avoid excessive force that could deform or damage the ring.

- Record Multiple Measurements: To ensure accuracy, take multiple measurements at different points around the circumference of the ring. This helps account for any irregularities in the bore or ring shape and provides a more representative average measurement.

Common Errors to Avoid

When measuring ring gaps, it is crucial to avoid common errors that can lead to inaccurate readings and potentially compromise engine performance. Here are some mistakes to watch out for:

- Using Incorrect Tools: Using improper tools or makeshift methods can result in inaccurate measurements. Invest in a reliable ring gap tool designed specifically for this purpose to ensure precise readings.

- Neglecting Ring Cleaning: Failing to clean the rings thoroughly before measurement can introduce debris or residue that affects the accuracy of the gap measurement. Take the time to clean the rings properly using a suitable solvent.

- Misalignment: Ensure that the ring is positioned correctly and perpendicular to the cylinder wall when taking measurements. Misalignment can lead to erroneous readings and affect the overall performance of the ring.

- Insufficient Pressure: Applying too little pressure when compressing the ring during measurement can result in a falsely tight gap reading. Use gentle but adequate force to simulate the ring’s operational position.

- Relying on Single Measurements: Taking only one measurement may not provide an accurate representation of the ring gap. Recording multiple measurements at different points around the ring circumference helps account for any variations and provides a more reliable average.

Adjusting Gap for Optimal Performance

Fine-tuning the Ring Gap

To achieve optimal engine performance, it is crucial to adjust the gap between piston rings accurately. The ring gap refers to the space left between the ends of the piston rings when they are installed in the engine. This adjustment plays a significant role in ensuring efficient combustion and overall engine health.

Benefits of Accurate Ring Gap Adjustment

Fine-tuning the ring gap based on engine specifications offers several benefits. Firstly, it helps maintain proper compression within the engine cylinders. By adjusting the gap, you can ensure that the rings fit snugly against the cylinder walls, minimizing any leakage of combustion gases. This results in improved compression ratios, which directly impact engine power and fuel efficiency.

Secondly, precise ring gap adjustment helps prevent excessive oil consumption. When the gap is too large, oil can seep into the combustion chamber, leading to increased oil consumption and emissions. On the other hand, if the gap is too small, it can cause excessive friction and wear on the rings, resulting in decreased engine performance over time. By fine-tuning the ring gaps, you can strike a balance that minimizes oil consumption while maintaining optimal lubrication.

Impact on Combustion Efficiency

The gap adjustment of piston rings also affects combustion efficiency. When the gap is set correctly, it allows for proper expansion and contraction of the rings during each stroke of the engine cycle. This ensures a good seal between the piston and cylinder wall, preventing blow-by and maximizing combustion efficiency.

Adjusting the ring gaps can help reduce blow-by gases that escape past the rings into the crankcase. Blow-by gases contain unburned fuel and combustion by-products, which can contaminate engine oil and lead to increased wear and reduced engine life. By optimizing ring gaps, you can minimize blow-by, keeping your engine cleaner and more efficient.

Achieving Optimal Performance

To adjust the ring gap for optimal performance, it is essential to refer to the manufacturer’s specifications for your specific engine model. These specifications typically provide recommended gap ranges based on factors like engine size, operating conditions, and intended use.

When adjusting the gap, it is crucial to use precision tools and follow the manufacturer’s instructions carefully. The process may involve removing the rings from the piston, carefully filing or grinding them to achieve the desired gap, and reinstalling them correctly. It is important to exercise caution and ensure that the gaps are uniform across all rings.

Common Mistakes to Avoid

Incorrect Gap Measurement

One of the most common mistakes made when dealing with piston ring gaps is incorrect gap measurement. It is crucial to measure the gap accurately to ensure proper engine performance. However, many people overlook this step or fail to use the correct tools for measurement.

The repercussions of incorrect gap measurement can be severe. If the gap is too small, it can lead to piston ring flutter, which can cause excessive wear and tear on the rings and cylinder walls. On the other hand, if the gap is too large, it can result in blow-by, where combustion gases leak past the rings and into the crankcase. This not only reduces engine power but also leads to increased oil consumption and potential engine damage.

To avoid these issues, it is essential to follow the manufacturer’s guidelines for measuring piston ring gaps. Use a feeler gauge specifically designed for this purpose and ensure that the rings are properly aligned during measurement. Taking the time to measure the gap accurately will help prevent costly engine problems down the line.

Insufficient Ring End Gap

Another common mistake is insufficient ring end gap. The ring end gap refers to the space between the ends of the piston ring when it is installed in the cylinder bore. This gap allows for expansion as the ring heats up during engine operation.

If the ring end gap is too small, it can lead to ring land breakage or scuffing of the cylinder walls. This occurs because there isn’t enough room for expansion, causing excessive pressure on the ring and cylinder surfaces. On the other hand, if the gap is too large, it can result in excessive blow-by and reduced compression.

To avoid these issues, always refer to the manufacturer’s specifications for ring end gap measurements. These specifications take into account factors such as engine size, operating conditions, and materials used. Follow these guidelines carefully to ensure proper ring end gap and avoid potential engine damage.

Improper Gap Adjustments

Lastly, improper gap adjustments can also cause significant problems with piston rings. Some individuals may attempt to adjust the ring gaps themselves without proper knowledge or tools. This can lead to incorrect gap settings, uneven gaps between rings, or damage to the rings themselves.

To avoid damaging the engine due to incorrect gap adjustments, it is best to leave this task to professionals or individuals with expertise in engine rebuilding. They have the necessary tools and knowledge to accurately measure and adjust the gaps according to the manufacturer’s specifications.

Maintenance Tips for Longevity

Regular Inspections

Regular inspections are crucial for maintaining the longevity of piston rings. By inspecting the rings at regular intervals, you can identify any potential issues early on and take appropriate action to prevent further damage. During these inspections, it is important to check for signs of wear, such as excessive carbon buildup or grooves on the surface of the rings. Make sure to examine the cylinder walls for any signs of scoring or pitting, as these can also affect the performance of the piston rings.

Gap Checks

Another important aspect of piston ring maintenance is performing gap checks. The gaps between the ends of the piston rings are designed to allow for expansion when the engine heats up. Over time, these gaps can become narrower due to wear and tear. It is essential to regularly measure and adjust these gaps to ensure optimal performance. If the gaps become too narrow, it can lead to increased friction and reduced sealing ability, resulting in decreased engine efficiency. On the other hand, if the gaps are too wide, it may cause oil consumption and loss of compression. Therefore, maintaining the correct gap size is crucial for the longevity of piston rings.

Proper Lubrication

Proper lubrication is key to ensuring that piston rings function optimally and last longer. Lubricating oil helps reduce friction between the rings and cylinder walls, minimizing wear and tear. It is important to use high-quality lubricants that are specifically formulated for piston rings and follow the manufacturer’s recommendations for oil change intervals. Regularly changing the oil and filter will help remove any contaminants that could potentially damage the rings. Make sure to monitor oil levels regularly to avoid running the engine with insufficient lubrication, which can lead to premature ring failure.

Avoiding Excessive Heat

Excessive heat can have a detrimental effect on piston rings, causing them to lose their elasticity and sealing ability. To prevent this, it is important to ensure that the engine does not overheat. Regularly check the cooling system and radiator for any leaks or blockages that could lead to overheating. Keep an eye on the temperature gauge and address any issues promptly to avoid potential damage to the rings.

Summary

In summary, understanding piston rings and their importance in engine health is crucial for optimal performance and longevity. Checking ring gaps and ensuring recommended clearances are maintained can prevent issues such as poor compression and oil consumption. Measuring ring gaps correctly and making necessary adjustments will help you achieve the best results. Avoiding common mistakes, such as using improper tools or techniques, is essential for accurate measurements. Regular maintenance, including periodic inspection and cleaning, will contribute to the longevity of your engine.

To ensure your engine operates at its best, take the time to understand piston rings and their role in engine performance. By following the recommendations outlined in this article, you can prevent potential problems and maximize the lifespan of your engine. Remember to regularly check and adjust ring gaps according to manufacturer guidelines, and avoid common mistakes that could compromise accuracy. By implementing these maintenance tips, you’ll enjoy a smoother-running engine with improved efficiency and reliability.

Frequently Asked Questions

How do piston rings affect engine performance?

Piston rings play a crucial role in engine performance by sealing the combustion chamber, preventing leakage of gases, and maintaining compression. They also aid in heat transfer and oil control, ensuring optimal engine efficiency and power output.

What is the importance of checking ring gaps?

Checking ring gaps is essential to ensure proper functioning of the piston rings. Incorrect gap clearances can lead to poor compression, oil consumption, or even engine damage. Regularly inspecting and adjusting ring gaps helps maintain engine health and performance.

What are recommended gap clearances for piston rings?

The recommended gap clearances for piston rings vary depending on the specific engine and manufacturer specifications. It is crucial to consult the engine manual or seek professional advice to determine the appropriate gap clearances for your specific application.

How should ring gaps be measured correctly?

To measure ring gaps accurately, place the ring in the cylinder bore without compressing it fully. Use a feeler gauge to determine the clearance between the ends of the ring. Rotate the ring gently to ensure uniform measurement around its circumference. Repeat this process for each ring.

Can adjusting ring gaps improve engine performance?

Adjusting ring gaps within the recommended specifications can optimize engine performance. Properly set gaps ensure efficient combustion, reduced blow-by, and improved sealing. However, it is important to follow manufacturer guidelines and consult experts for optimal adjustments tailored to your engine’s needs.