Want to improve your engine’s performance? Want to improve efficiency? Piston rings are the answer. These small parts are important for internal combustion engines. They seal the space between the piston and cylinder wall. Not all piston rings are the same.

Bad piston rings can make your engine less powerful, use more oil, and even damage it. Choose high-quality piston rings that can withstand your engine’s demands.

Learn about the key factors to consider when choosing the best piston rings for your engine.

Key Takeaways

- Understanding the basics of piston rings is crucial for maintaining the efficiency and performance of your engine.

- When choosing the right piston ring size, consider the engine specifications and consult us if necessary.

- Exploring the costs associated with piston rings can help you make an informed decision and budget accordingly.

- Analyzing prices from different suppliers can help you find the best deal without compromising on quality.

- Finding affordable options for piston rings doesn’t mean sacrificing quality; consider reputable brands and look for discounts or promotions.

- Regular maintenance and inspection of piston rings can prevent costly repairs and extend the lifespan of your engine.

Understanding Basics

Definition and Primary Function

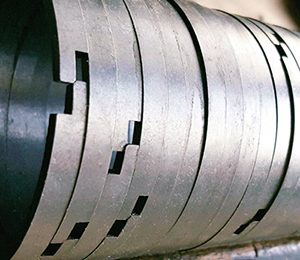

A piston ring is a vital component of an internal combustion engine. It is a circular metal ring that fits tightly into the grooves (known as ring lands) on the outer surface of the piston. The primary function of a piston ring is to create a seal between the piston and the cylinder wall, preventing leakage of combustion gases and oil.

Piston rings serve as a barrier, ensuring that the high-pressure gases produced during the combustion process are contained within the combustion chamber. By forming a tight seal, they prevent these gases from escaping past the piston and into the crankcase. This sealing action is crucial for maintaining optimal compression ratios and maximizing engine power output.

Importance in Engine Performance

Piston rings play a crucial role in ensuring proper engine performance. They contribute to efficient combustion by maintaining compression within the cylinders. Without effective rings, there would be significant loss of compression, resulting in reduced power output, decreased fuel efficiency, and increased emissions.

Piston rings help regulate oil consumption within the engine. They scrape excess oil from the cylinder walls as the piston moves up and down, preventing it from entering the combustion chamber. This not only reduces oil consumption but also minimizes carbon buildup on the piston and cylinder walls, which can lead to engine damage over time.

Types of Piston Rings

There are several types of piston rings available in the market, each designed to fulfill specific requirements based on engine design and operating conditions:

- Compression Rings: These are the topmost rings and are responsible for sealing the combustion chamber. They provide the primary sealing function and withstand high temperatures and pressures.

- Oil Control Rings: Positioned below the compression rings, oil control rings regulate oil distribution along the cylinder walls. They prevent excessive oil from entering the combustion chamber while ensuring adequate lubrication for smooth piston movement.

- Second Compression Rings: Some engines feature a second set of compression rings to enhance sealing and improve overall engine performance. These rings provide additional compression and help reduce blow-by, enhancing combustion efficiency.

- Taper-Faced Rings: Taper-faced rings have a unique design with a tapered face that improves oil control and reduces friction. They are commonly used in high-performance engines where minimizing friction is crucial.

- Gapless Rings: Gapless rings are designed to eliminate the small gaps found in traditional piston ring sets. This helps improve compression, reduce blow-by, and optimize engine power output.

Understanding the basics of piston rings, their primary function, and the different types available in the market is essential for anyone interested in engine performance and maintenance.

Choosing Right Size

Importance of Selecting the Correct Size

Selecting the right size of piston rings is crucial for the optimal performance and longevity of an engine. The piston rings play a vital role in sealing the combustion chamber, preventing the leakage of gases and ensuring efficient power generation. Using incorrectly sized piston rings can lead to various issues that can negatively impact the engine’s performance and overall reliability.

Measuring and Determining the Appropriate Size

To choose the correct size of piston rings, accurate measurements are essential. Here are some tips on how to measure and determine the appropriate size:

- Cylinder Bore Measurement: Start by measuring the cylinder bore diameter using a micrometer or a bore gauge. Take multiple measurements at different points along the cylinder to ensure accuracy. This measurement will serve as the basis for selecting the piston ring size.

- Ring Groove Width: Measure the width of the ring groove in the piston. This measurement is crucial for determining the correct width of the piston rings. It is important to note that different engines may have different ring groove widths, so it is essential to consult the engine manufacturer’s specifications.

- Ring End Gap: The ring end gap refers to the space between the ends of the piston ring when it is installed in the cylinder bore. It is important to measure and adjust the ring end gap according to the engine manufacturer’s recommendations. Incorrect ring end gap can result in poor compression and oil consumption.

- Consult Manufacturer Specifications: Always refer to the engine manufacturer’s specifications and guidelines for selecting the appropriate piston ring size. They provide specific recommendations based on factors such as engine displacement, operating conditions, and intended use.

Consequences of Using Incorrectly Sized Piston Rings

Using incorrectly sized piston rings can have detrimental effects on engine performance and reliability. Here are some potential consequences:

- Poor Compression: Incorrectly sized piston rings may not provide the necessary compression, leading to decreased engine power and efficiency. This can result in reduced fuel economy and overall performance.

- Oil Consumption: Ill-fitting piston rings can allow oil to pass into the combustion chamber, leading to increased oil consumption. Excessive oil consumption not only affects engine performance but can also lead to fouled spark plugs and increased emissions.

- Excessive Wear: When piston rings are too loose or too tight, they can cause excessive wear on the cylinder walls or the rings themselves. This can lead to decreased engine life and the need for premature repairs or replacements.

- Blow-by: Incorrectly sized piston rings may allow combustion gases to bypass the rings and enter the crankcase, resulting in blow-by. Blow-by can contaminate the engine oil, reduce its lubricating properties, and contribute to increased engine wear.

To get the best out of your engine, choose the right size of piston rings.

Exploring Costs

Factors Affecting the Cost of Piston Rings

The cost of piston rings is influenced by several factors that contribute to the overall price. Understanding these factors can help you make an informed decision when purchasing piston rings for your engine.

Material Quality and Performance

One of the primary factors that affect the cost of piston rings is the quality of materials used in their construction. Piston rings are typically made from various materials, including cast iron, steel, and even advanced materials like ceramic or nitride coatings. Higher-quality materials tend to be more expensive but offer enhanced durability and performance.

Design Complexity and Manufacturing Techniques

The design complexity of piston rings can also impact their cost. Some piston rings feature intricate designs with multiple grooves and specialized features that optimize their performance. These complex designs require precision manufacturing techniques, which can increase the production costs and ultimately affect the price of the piston rings.

Size and Compatibility

The size of the piston rings plays a crucial role in determining their cost. Different engines require specific sizes of piston rings to ensure proper fit and function. Custom-made or rare sizes may be more expensive due to their limited availability. It is essential to choose the correct size of piston rings for your engine to avoid any compatibility issues.

Standard vs. Performance Piston Rings

When it comes to pricing, there is a notable difference between standard and performance piston rings. Standard piston rings are designed for everyday use and are generally more affordable compared to performance piston rings. Performance piston rings, on the other hand, are engineered to withstand higher temperatures, pressures, and RPMs, making them ideal for high-performance engines. However, this increased performance often comes at a higher price point.

Additional Considerations

In addition to the factors mentioned above, other factors can influence the cost of piston rings. These include brand reputation, market demand, and availability. Well-known brands with a strong reputation for quality may charge a premium for their piston rings. Similarly, if there is high demand for a particular type of piston ring or if it is a rare find, the price may be higher due to limited availability.

Analyzing Prices

Price Variations Among Manufacturers

When it comes to purchasing piston rings, one of the key factors to consider is the price. The prices of piston rings can vary significantly among different manufacturers. It’s important to analyze these variations and understand the factors that contribute to them.

Material and Technology Impacting Prices

The material and technology used in the manufacturing process of piston rings play a crucial role in determining their prices. Different materials, such as cast iron, steel, and various types of alloys, have varying costs associated with them. Similarly, advanced technologies used in the production of piston rings, such as plasma spraying or diamond coating, can also influence the prices.

Piston rings made from high-quality materials tend to be more expensive compared to those made from lower-grade materials. This is because premium materials offer enhanced durability, better heat resistance, and improved performance. Manufacturers investing in advanced technologies for piston ring production may charge higher prices due to the added value these technologies bring.

Additional Costs to Consider

When analyzing the prices of piston rings, it’s essential to take into account any additional costs that may be associated with their purchase. While the initial price of the piston rings is a significant consideration, it’s equally important to factor in other expenses that might arise.

One such cost is the installation fee. Depending on your expertise and experience with engine components, you may choose to install the piston rings yourself or seek professional assistance. If you opt for professional installation, there will be an additional fee involved.

Furthermore, it’s worth considering any warranty or guarantee offered by the manufacturer. Some manufacturers provide extended warranties or guarantees for their piston rings, which might come at a slightly higher price point but offer peace of mind in terms of product quality and reliability.

Finding Affordable Options

Purchasing in Sets or Bulk Quantities

When it comes to finding affordable piston rings, one option to consider is purchasing them in sets or bulk quantities. Buying piston rings in sets can often be more cost-effective compared to buying individual rings. This is because manufacturers often offer discounts when selling rings as a set, allowing you to save money while ensuring that all the necessary rings are included.

By purchasing piston rings in bulk quantities, you can also enjoy significant cost savings. Many suppliers offer discounts for larger orders, making it an attractive option for those who need multiple rings or want to stock up on spare parts. Not only does buying in bulk help you save money, but it also ensures that you have extra rings on hand for future maintenance or repairs.

Another benefit of purchasing piston rings in sets or bulk quantities is the convenience it provides. Instead of having to search for and purchase individual rings every time you need one, buying in sets or bulk allows you to have a ready supply of rings readily available. This can save you time and effort, especially if you frequently work with piston engines.

Exploring Alternative Options

In addition to purchasing piston rings in sets or bulk quantities, there are alternative options available for finding affordable options. One such option is to explore online marketplaces and auction websites. These platforms often have sellers offering piston rings at discounted prices. However, it is important to exercise caution and ensure that you are purchasing from reputable sellers to avoid counterfeit or low-quality products.

Another alternative option is to consider aftermarket piston rings. Aftermarket parts are produced by third-party manufacturers and are often priced more competitively compared to original equipment manufacturer (OEM) parts. While some people may prefer OEM parts for their reliability and quality assurance, aftermarket piston rings can be a viable and more affordable alternative without compromising performance.

Ask local auto shops or engine rebuilders for affordable piston rings. These professionals often have access to many suppliers and may be able to help you find the right piston rings at a good price.

Closing Thoughts

In conclusion, understanding the basics of piston rings is crucial when it comes to choosing the right size and exploring costs. By analyzing prices and finding affordable options, you can make an informed decision that suits your needs and budget. Remember, the size and quality of the piston ring directly impact your engine’s performance and longevity.

Now that you have a better understanding of piston rings, it’s time to take action. Evaluate your engine’s needs, consider your budget, and make an educated choice when purchasing piston rings. Don’t settle for subpar options that may compromise your engine’s efficiency or durability. Instead, invest in high-quality piston rings that will ensure optimal performance and reliability. By following these guidelines, you can enhance your engine’s lifespan and enjoy a smoother driving experience. Happy motoring!

Frequently Asked Questions

What are the basics of piston rings?

Piston rings are essential components in an engine that help seal the combustion chamber, ensuring maximum power and preventing oil leakage. They play a crucial role in maintaining optimal compression and reducing friction between the piston and cylinder wall.

How do I choose the right size of piston rings?

To select the correct size, measure the bore diameter of your engine’s cylinder accurately using a micrometer. Consult the manufacturer’s specifications or refer to a reliable automotive guide to determine the appropriate ring size based on the measurements.

What factors should I consider when exploring the costs of piston rings?

When analyzing costs, consider factors such as material quality, brand reputation, and durability. Opting for high-quality rings may result in longer-lasting performance and reduced maintenance expenses in the long run.

How can I analyze prices effectively when purchasing piston rings?

To analyze prices, compare offerings from different suppliers or manufacturers. Take into account factors like warranty coverage, customer reviews, and additional services provided. This comprehensive evaluation will help you make an informed decision while considering both cost and quality.

Are there affordable options available for purchasing piston rings?

Yes, there are affordable options available without compromising quality. Consider reputable aftermarket brands that offer competitive pricing while maintaining high standards. However, it is vital to ensure that these options meet the necessary specifications for your engine to avoid any potential issues.