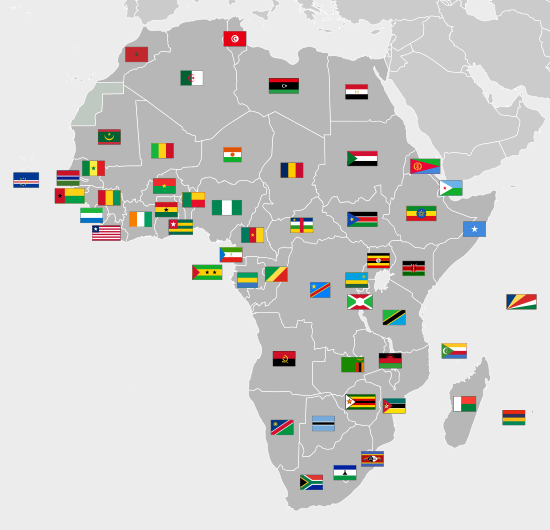

Africa Piston rings

We provide high-quality piston rings for tropical climates and excellent local after-sales service.

+

Year+

service life.

Our product application scenarios

Car

Our piston rings last a long time and keep engines running smoothly. They are made for high speeds and tough conditions.

Motorcycle

Our piston rings make engines last longer and run more smoothly. They are designed for high RPM and tough conditions.

Small industrial machinery

Our piston rings deliver exceptional wear resistance and efficient sealing performance in industrial machinery, ensuring long-term stability under extreme conditions.

The product is high quality from start to finish.

01

Ring Profile Machining

Precise Shape of the Ring:

- The precise shape of the ring is crucial for proper sealing within the engine cylinder.

Use of CNC Machines:

- CNC (Computer Numerical Control) machines are commonly used to achieve the exact dimensions and geometry required.

Machining Inner and Outer Diameters and Axial Width:

- The ring’s inner and outer diameters, and axial width are meticulously machined to strict tolerances.

Machining the Profile of the Ring Face:

- The profile of the ring face is also meticulously machined to ensure it meets strict tolerances.

02

Heat Treatment

Boosting Mechanical Properties with Heat Treatment:

- To make our piston rings even tougher, we put them through a heat treatment process.

Precise Heating:

- This means heating the rings to just the right temperature.

Controlled Cooling:

- Then, we cool them down gradually.

Quenching and Tempering:

- This process, called quenching and tempering, gives the rings extra strength.

Enhanced Resilience and Wear Resistance:

- It makes our rings more resilient and much more resistant to wear.

03

Quality Control

Ongoing Quality Control:

- We keep a close eye on quality throughout the entire manufacturing process.

Stage-by-Stage Inspections:

- Our rings go through inspections at various stages to ensure they meet our strict standards.

Precise Dimensional Checks:

- We perform precise dimensional checks.

Surface Finish Checks:

- Evaluating the surface finish is part of our thorough process.

Coating Integrity Verification:

- We also verify the integrity of the coating.

Rejecting Subpar Rings:

- Any rings that don’t meet our criteria are rejected.

04

Packaging and Distribution

Passing Quality Control:

- Once the piston rings pass our rigorous quality control checks…

Packaging for Distribution:

- …they are carefully packaged and prepared for distribution.

Destinations:

- Our rings are shipped to various engine manufacturers, repair shops, and aftermarket suppliers.

Importance of Proper Packaging:

- Proper packaging is crucial to prevent any damage during transport.

Partner with us in the Philippines!

Partner with us in the Philippines and experience the reliability of our high-quality piston rings. We offer excellent local support to ensure your engines perform at their best. Partner with us for trusted products in the Philippine market.

Products for the Africa tropical climate.

Our car accessories are great in tropical countries!

We are a 20-year-old company known for quality and on-time delivery. KRK Fires is a trusted brand that develops, manufactures, and sells engine parts. We have been in the Africa for over 10 years. We make piston rings, pistons, and liners. We make engines and engine parts for companies in Europe, the United States, South America, Africa, and Asia.

John Doe

48-hour response

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

1-on-1 inspection

Our products are 1:1 inspected to ensure your safety.

Our professional blog

We’ll teach you the industry’s best practices.

Download the ultimate solution now. In this eBook, you will learn:

- Our complete catalog of piston ring types

- Key applications for piston rings across industries

- Efficient and cost-effective installation and transportation solutions for piston rings

- And much more...